New Arrivals

Meet The Makers

Many of our makers have honed their craft over many years with us, often decades. Their passion, commitment, attention to detail, grit, determination, and humour are a joy to behold every single day.

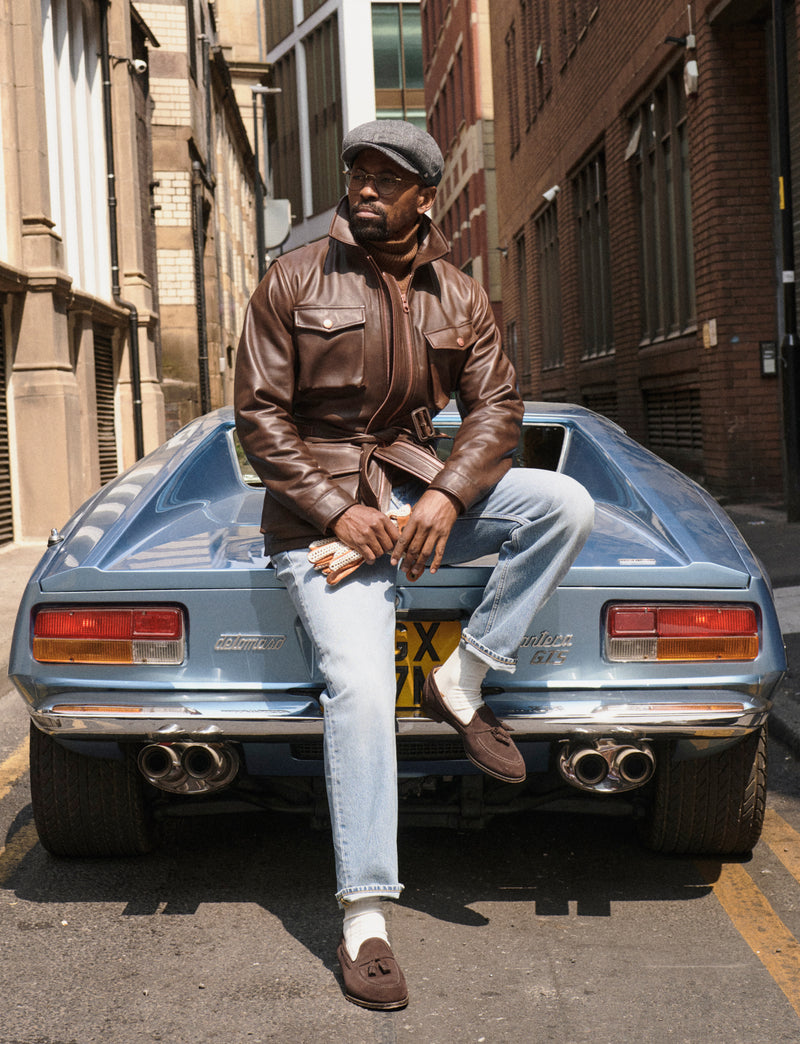

The Heroes

A curated edit of our most popular and iconic outerwear crafted from the only the finest regionally-sourced trims, materials and luxury yarns.